Vlt Micro Drive Fc 51 User Manual

- Vlt Micro Drive Manual

- Vlt Micro Drive Fc 51 User Manual Software

- Danfoss Micro Drive Fc 51

- Vlt Micro Drive Fc 51 User Manual Instructions

- Vlt Micro Drive Fc 51 User Manual 2016

Compact VLT quality

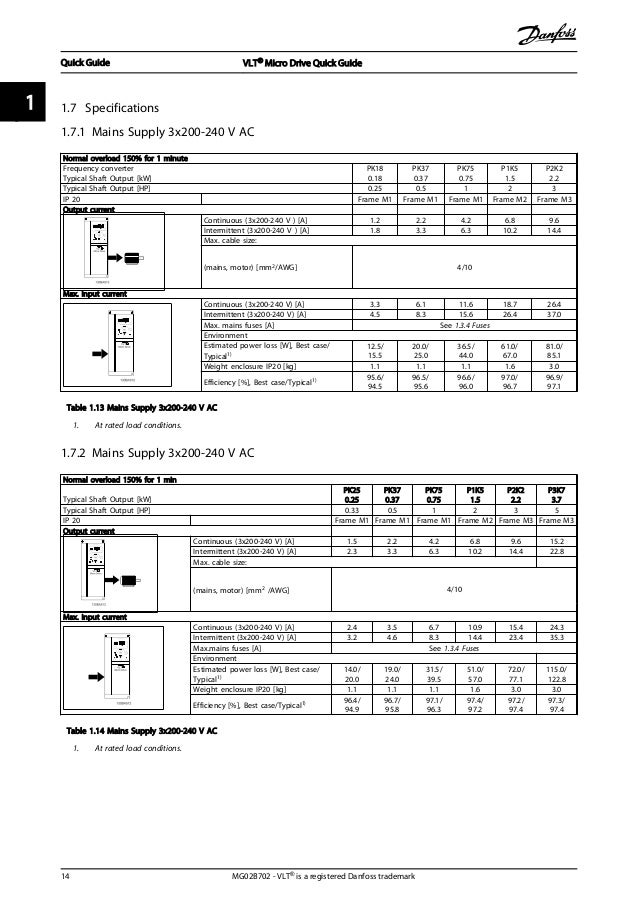

VLT Documents, Software, Manuals. VLT® Micro Drive FC 51; VLT® HVAC Drive FC 102; VLT® AutomationDrive FC 301 / FC 302; VLT® AQUA Drive FC 202; VLT 2800; VLT 3000 / 5000 / 6000 Drives Conversions; VACON Documents, Software. VACON 100; VACON 100 FLOW; VACON 100X; VACON NXP Air Cooled; VACON NXP Liquid Cooled; VACON NXC; VACON 20, 20 X. VLT Micro Drive FC 51 Series This Operating Instructions can be used for all VLT Micro Drive FC 51 frequency con-verters with software version 2.2x. The software version number can be read in parameter 15-43. 1 Safety VLT® Micro Drive FC 51 Operating Instructions 6 MG.02.A4.02 - VLT® is a registered Danfoss trademark 1. Maximum strength with reduced installation costs. The VLT ® Micro Drive FC 51 is small and yet powerful and built to last. Panel space can be saved and installation costs reduced thanks to its compact size and minimal commissioning requirements.

The Danfoss VLT® Micro Drive is a genuine VLT® frequency converter with unsurpassed reliability, user-friendliness, condensed functionality, and extremely easy to commission. Terminal numbers are named in the same manner as in the rest of the VLT® family. It’s developed and manufactured by Danfoss Drives, the leading drives experts since 1968 and creators of VLT® – The Real Drive.

User Friendly

- VLT Micro Drive share the user-friendliness of the VLT family.

- Plug and play – minimum effort minimum time

- Minimum Commissioning – save time

- Copy settings via local control panel – simple set up of multiple drives

- Intuitive parameter structure – minimal manual reading

Reliable

VLT Micro Drive is a full member of the VLT® family sharing the overall quality of design, reliability and user-friendliness.

High quality components and genuine VLT® solutions makes VLT® Micro Drive extremely reliable.

- Optimum heat dissipation – Longer lifetime

- High quality electronics/capasitors – Low lifetime cost

- All drives full load tested from factory – High reliability

- Earth fault, temperature and short circuit protection – Lean operation

- Circuit boards well protected and coated – Increased robustness

Small drive – high performance

Despite the compact size and the easy commissioning, VLT® Micro Drive can be set up to perform perfectly even in complex application set-ups. Approximately 100 parameters can be set to optimize energy efficiency and operation.

- Process PI-controller – No need for external controller

- Automatic Energy Optimizer (AEO) – Less energy consumption

- Automatic Motor Adaptation (AMA) – Exploit motor’s full potential

- 150% motor torque up to 1 minute – Replace need for bigger drive

- Flying start (catch a spinning motor) – Lean operation – more up-time

- Electronic Thermal relay (ETR) – Replace external motor protection

- Smart Logic Controller – Often makes PLC ommissible

- Built-in RFI filter – Save cost and space

Ensured Reliability and Maximum Up / Time

Real space saving side-by-side

A compact book style design allows real side by side mounting without derating.

Minimum penetration of dust

VLT® MICRO Drive is designed to keep the forced ventilation away from the electronics. Printed circuit boards are well protected inside the drive.

Built-in RFI

Radio disturbance from motor cables is limited with the built-in RFI filter allowing for 15 m motor cables (screened). Meets EU norms.

Built-in brake functions

With built in DC and AC brake functions, VLT® Micro Drive can transform kinetic energy in the application into braking power to slow down the motor. A brake chopper is built-in the drives from 1.5 kW upwards.

Coated electronics are standard

All VLT® Micro Drive comes with coated electronics for longer lifetime and reliability.

Vlt Micro Drive Manual

Energy efficiency 98%

Vlt Micro Drive Fc 51 User Manual Software

High quality VLT® power modules ensure cool running of the drive due to low losses.

Intelligent heat management

Process heat is removed through the heat sink, leaving electronics protected from dust and dirt from production.

Effective heat sink

An effective heat sink easily removes heat from the electronics, extending lifetime and reliability of the drive.

50˚ ambient temperature

Highly efficient cooling allows up to 50˚ ambient temperature.

Hot pluggable display – with or without potentiometer

- LCP without potentiometer IP 54

- LCP with potentiometer IP 21

- Remote mounting kit

- LCP copy function

- Parameter numbers and values visible simultaneously

- Unit indications (A., V, Hz, RPM, %, s, HP and kW)

- Rotation direction indication

- Setup indication – 2 setup

- Removable during operation

- Up- and download functionality

Large figures, easy to read

Two point hospital update manual download for windows 7. This is just the beginning!

- Display readable from distance

- Operation buttons areilluminated when active.

Quick Menus

- A Danfoss defined Quick Menu

- Basic settings

- PI controller

Menu structure

- Based on the well-known matrix from the VLT® family

- Easy shortcut for the experienced user

- Edit and operate in different set-ups simultaneously

Danfoss Micro Drive Fc 51

Built-in Smart Logic Controller

The smart logic controller is a simple, and yet very clever way to have your drive, motor and application working together.

The smart logic controller is able to monitor any parameter that can be characterized as “true” or “false”.

This includes digital commands and also logic expressions, which allows even sensor outputs to influence the operation. Temperature, pressure, flow, time, load, frequency, voltage and other parameters combined with the operators “>”, “<”, “=”, “and” and “or” forms logic expressions that are false or true.

That is why Danfoss calls it a “logic” controller. As a result of this, you can program the controller to react on literally any event.

For more specifications, please download the Acrobat

Danfoss Micro Drive Specification Sheet

FC51 Ordering Information

| 200 -240V | 400V | ||||

| Power | Current | 1 phase | 3 phase | Current | 3 Phase |

| (kW) | (I-nom.) | (I-nom) | |||

| 0.18 | 1.2 | 132F 0001 | |||

| 0.25 | 1.5 | 132F 0008 | |||

| 0.37 | 2.2 | 132F 0002 | 132F 0009 | 1.2 | 132F 0017 |

| 0.75 | 4.2 | 132F 0003 | 132F 0010 | 2.2 | 132F 0018 |

| 1.5 | 6.8 | 132F 0005 | 132F 0012 | 3.7 | 132F 0020 |

| 2.2 | 9.6 | 132F 0007 | 132F 0014 | 5.3 | 132F 0022 |

| 3.0 | 7.2 | 132F 0024 | |||

| 3.7 | 15.2 | 132F 0016 | |||

| 4.0 | Micro drives from 1.5kW and up have built in brake chopper | 9.0 | 132F 0026 | ||

| 5.5 | 12.0 | 132F 0028 | |||

| 7.5 | 15.5 | 132F 0030 | |||

| 11.0 | 23.0 | 132F 0058 | |||

| 15.0 | 31.0 | 132F 0059 | |||

| 18.5 | 37.0 | 132F 0060 | |||

| 22.0 | 43.0 | 132F 0061 | |||

Vlt Micro Drive Fc 51 User Manual Instructions

VLT Control Panel LCP 11 : WIthout potentiometer : 132B0100

Vlt Micro Drive Fc 51 User Manual 2016

VLT Control Panel LCP 12 : With potentiometer : 132B0101